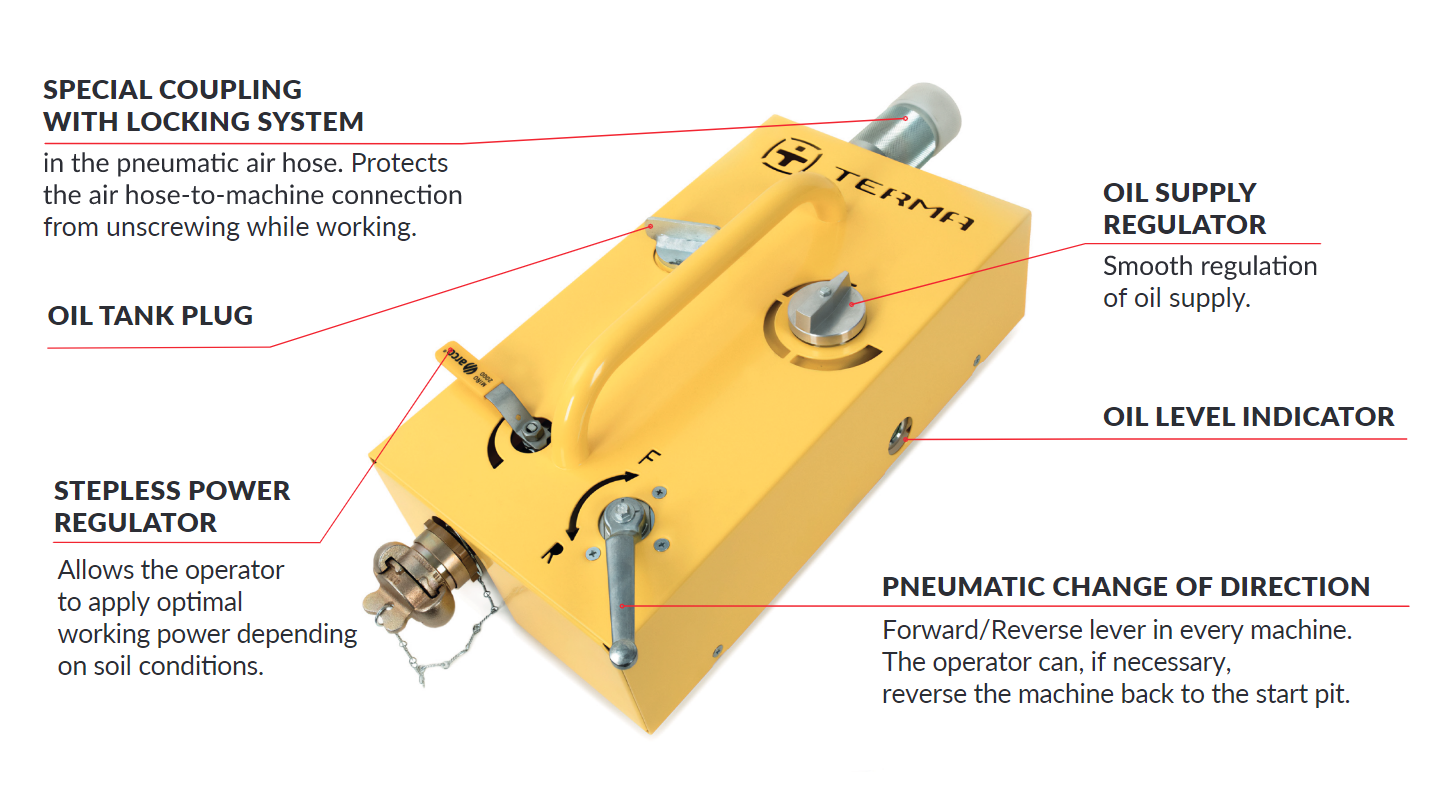

The control station, commonly referred to as the Oiler, is a standard component of every MAX Basic Set. It is used to lubricate and control the operation of the piercing machine. The Oiler is equipped with pneumatic valves by which you can regulate the speed of operation, and the direction of operation (front to back).

It also performs the function of lubricating the "mole" (as its name implies), and is equipped with an oil tank and dispenser. The supply air flows through the oiler, in which an oil mist is created. In this form, through the air supply/control hose, it goes to the pneumatic mole or rammer to ensure proper working conditions for the moving parts of the piercing machine. A lubrication intensity regulator is placed on the station.

Technical data of the Station for K180S, K130S:

- length (including end caps): 665 mm

- width: 232 mm

- height: 180 mm

- weight: 15.8 kg

- tank capacity: 3,1 l

- working pressure: 7 atm

Technical data of the Station for K95S, K75S, K65S:

- length (including end caps): 534 mm

- width: 232 mm

- height: 180 mm

- weight: 11.4 kg

- tank capacity: 1,1 l

- working pressure: 7 atm

Technical data of the Station for T240:

- length (including end caps): 650 mm

- width: 320 mm

- height: 310 mm

- weight: 24 kg

- tank capacity: 5,2 l

- working pressure: 6 atm

Each size of mole, as you can see, has a Lubricator with Controls dedicated to that particular size of machine. However, it is possible to use Lubricator with Controls designed for larger piercing machines to work with smaller moles. All you need to do is to get a dedicated adapter / converter.

For lubrication, use our EkoMAX oil, made of harmless components that are rapidly biodegradable, and is certified by the PZH.